We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies.

- Fast order processing

- All products in stock

- 24/7 Support

- Questions? Call +31(0)10 - 479 15 11

More information about DG208/25SRHDOMD

- Partnumber

- DG208/25SRHDOMD

- Brand

- Ermeto

- Manufacturer

- Parker Hannifin

- Crossreference Parker

- DG208/25SRHDOMDCF

- Material

- Steel, Cr(VI)-free

- Series

- Heavy Series

- Tubesize

- 25S - M36×2.0

- Connection Size

- 1 BSP Male

- Sealing

- Eolastic softseal

- Type

- Body only

- Weight (KG)

- 1.271700

- Customs Tariff Number

- 73079290

- Country of Manufacture

- Germany

- Box Qty

- 1

- Sales Unit

- Piece

- Lead Time (days)

- 30

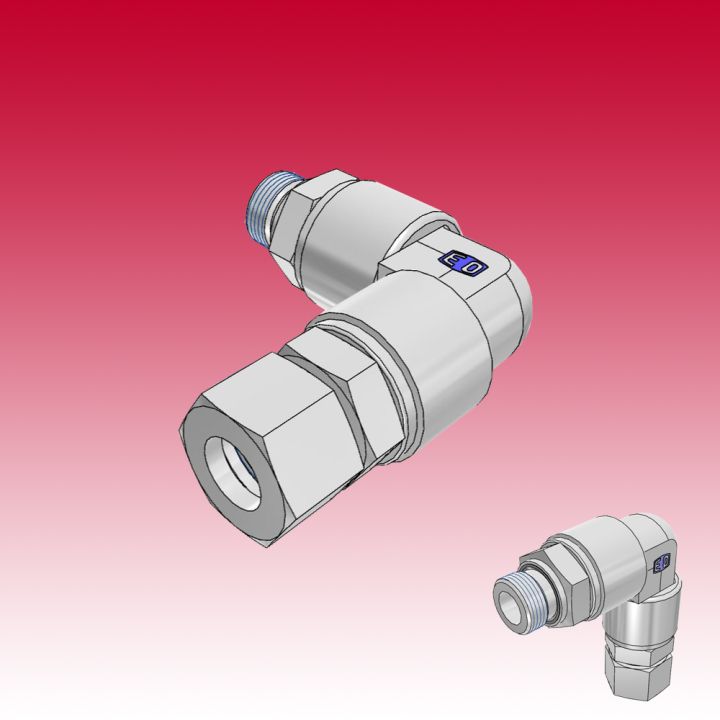

Details of the DG208/25SRHDOMD

Parker ball bearing rotary fittings are used to connext a fixed point to a rotating, swinging or moving part via hoses. These products are used to prevent torsion and small hose radius. The ball bearing rotary fittings are suitable for hydraulic oils and lubricants on minerl oil base as flow media. The construction of this service-proved product range is characterized by a compact, maintenance-free construction. The ball bearing rotary fittings have a combined ball and plain bearing with constant lubrication, a low starting torque and wear-resistant annular piston sealings.

Markets:

- Chemical Industries

- Plant engineering

- Power stations

- Cable storage

Applications:

- Suitable for general hydraulic applications.

Features/ Benefits of the ball bearing rotary fittings:

- Parker ball bearing rotary fittings help to avoid torsion of hoses and therefore improve the life cycle of these products

- Parker ball bearing rotary fittings have a Cr(VI)free surface, which is highly corrosion resistant (in average 500 hours against white rust). This surface renews the life cycle of the component and the entire hydraulic system.

- The construction of the ball bearing fittings is maintenance-free, so that the costs for maintenance will be reduced.

Technical specifications:

Materials:

- Casing, body nut of steel. Annular piston sealing: POM/FKM. Eolastic sealing: NBR, also available in FKM. Surface: Cr(VI)free.

Temperature:

- Nominal temperatures: -14 °C up to +80 °C

Construction Systems:

- 8 different versions with one rotational axis. Multiaxial rotary couplings on request. Tube connections according to DIN 2353, series S. Maximum working pressure 350 bar (peak pressure)

- Male stud sealing by Eolastic seals of NBR

- Male stud with metric parallel or BSPP thread.